Description

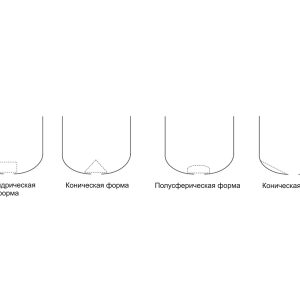

Outlet collector is located under the reactor packing. It collects the product in the direction of the outlet and prevents catalyst leakage. The packing bed is a set of inert material and catalyst of various types with a certain size and density. The outlet collector has a prefabricated structure consisting of segments. The segments are based on slit screen technology and made of triangular wire. Perforated and mesh screens are used too. The segments are installed in the reactor on the bottom above the outlet fitting and are interconnected with fasteners. A cord and ceramic fiber gaskets are used to seal the gaps and provide tightness. In upflow reactors, the collector is installed below the top outlet fitting. Design features are determined considering loads from the catalyst layer and pressure drop.