Description

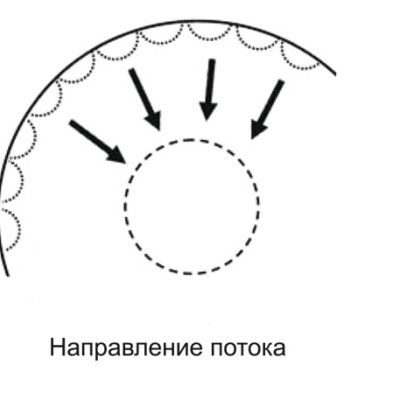

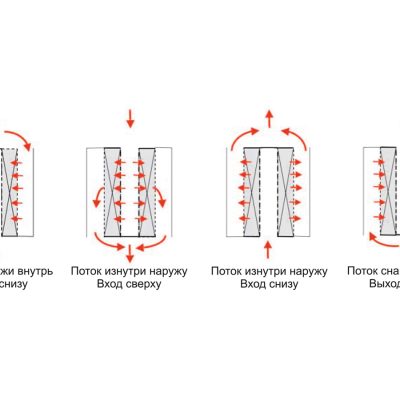

Outer basket is an outer slit screen in radial flow reactors. It is located along the inner vessel surface. They are usually installed inside vertical reactors and distribute or collect the flow. The outer surface of the basket contacts the catalyst and is usually made of triangular wire. It can be used to move the flow towards the center or outwards the center. Outer baskets consist of segments assembled by fasteners. The space between the baskets and the central pipe in the upper part is closed with a blind plate. The flow area of the baskets is calculated to ensure stable operation in a wide range of flow rates. Cord or ceramic fiber gaskets are used to seal the gaps and ensure tightness. Basket’s design features are determined according to the given loads from the catalyst layer and the pressure drop.