Description

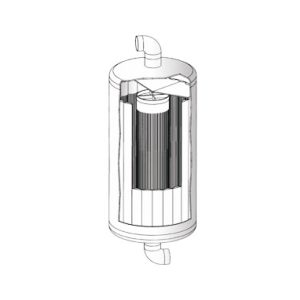

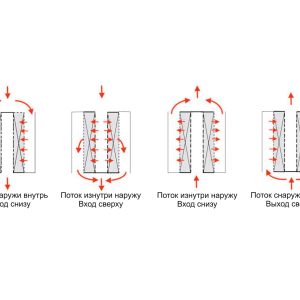

This device is a central slotted screen in radial flow reactors. It’s outer surface contacts the catalyst layer and is made as a slit screen of triangular wire. This device holds the packing and directs the flow towards the outlet. There are versions for flow going towards the center or outwards the center. The central pipe is installed in the reactor on support elements above the outlet fitting. The flow area of the outer surface of the pipe is calculated to ensure operation within the wide range of flow rates.