We are ready to design and produce industrial silencers for refineries, power plants and for oil / gas engineering enterprises. The silencers are mounted on piplenes, tanks and other units with high inner pressure. They muffle noise on blowdowns or pressure releases.

Main features and parameters

Medium superheated water steam, air, other gaseous media

Medium params superheated water steam

Pressure before silencer, kg/cm2 5 to 140

Silencer temperature, C 150 to 565

Max. expenditure, t/h air and other gases — from 1 to 360

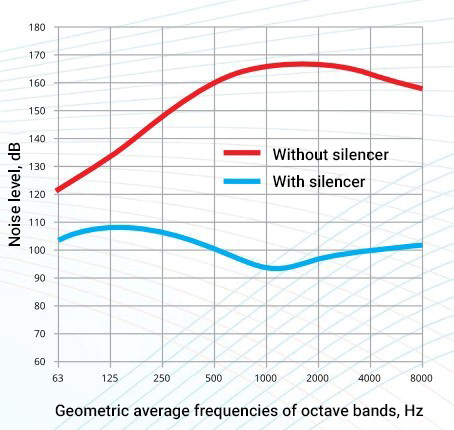

Nax. noise, dBA under 85

Expected lifespan, years 10 (or under 1000 launches)

Seismicity of the deployment area up to 6,0 at MSK-64 scale

Types of silencers

ShGEmPG — muffle the noise of emergency steam release

ShGEmV — muffle the noise of fans

ShGEmCK — muffle the noise of centrifugal compressors

ShGEmG — muffle the noise of gas pipelines

ShGEmK —noise reduction enclosures

Production

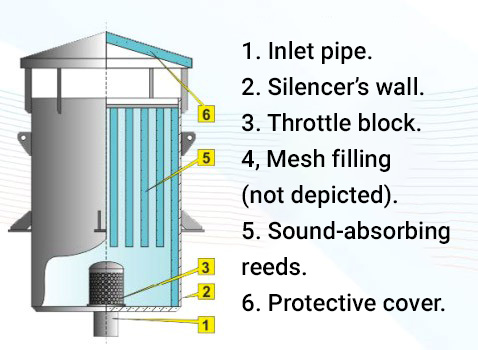

We use a special technology for muffler production: our products consist of dissipative and throttled parts which fractionize the flow. This drops the pressure of air (or steam, or gas) and reduces the noise level. Materials for silencers are selected individually for every case, depending on the temperature and agressiveness of environment. Noise levels meet GOST “Organic fuel energy units for power plants. Common requirements to noise supression.” and never exceed 85 dBA.