Description

This design with a perforated flat surface seems to be the most commonly used type in the processing industry. It is frequently used due to its excellent performance, low costs and low operational requirements. The absence of any moving mechanical parts makes it the simplest design of tray types.

Sieve plates are resistant to heavy contamination and provide a great performance. However, their effectiveness is considered low or moderate, and, in addition, there are very few options to change the operating mode.

Double-flow trays have no partitions or downcomers, so the liquid level in the tray depends on vaporization rate. The optimal performance depends on selected diameter of the hole. However, small holes are getting clogged easily.

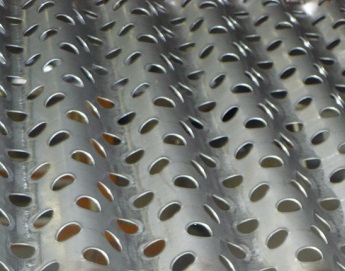

JSC PO STRONG can produce special double-flow trays Ripple® Tray, licensed by Stone & Webster.

These double-flow channeled trays reduce the contamination degree without disturbing the steam/liquid distribution, and are made of a perforated sheet with a large surface area for the movement of steam and liquid.

Our experience shows that smaller openings provide better performance with the same clearance area. This type of trays has lower performance and less flexible adjustment options than traditional trays with downcomers. Nevertheless, these corrugated trays have a high productivity and a high resistance to corrosion and contamination.